|

|

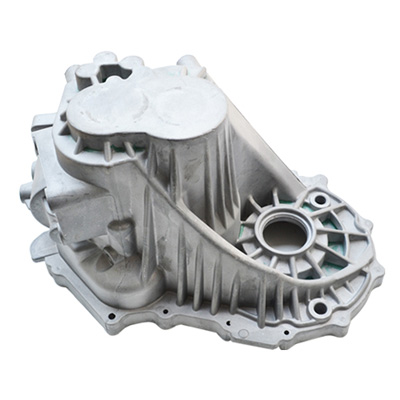

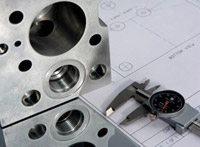

Details Die Casting Die casting is a versatile, efficient and economical process for producing engineered metal parts. The metal die-casting products’ method is especially suited for applications where large quantities of small- to medium-sized parts are needed with good detail, fine surface quality and dimensional consistency. Most die cast molds are made from non-ferrous metals, specifically zinc and aluminum. The level of versatility offered by die casting has placed it among the highest volume products made in the metalworking industry. Die casting is a versatile, efficient and economical process for producing engineered metal parts. The metal die-casting products’ method is especially suited for applications where large quantities of small- to medium-sized parts are needed with good detail, fine surface quality and dimensional consistency. Most die cast molds are made from non-ferrous metals, specifically zinc and aluminum. The level of versatility offered by die casting has placed it among the highest volume products made in the metalworking industry. The continued growth of the die-casting process in many industries is leading to demands for long production runs and therefore dies with longer lifespan. The benefits of Die-Casting: λ. Excellent dimensional accuracy. λ. Smooth or specific textured cast surfaces. λ. Thinner wall sections are possible over other methods of metal casting. λ. Inserts can be cast in as part of process (i.e. threaded inserts, shafts, spigots, pressings). λ. Reduced number of secondary operations / machining. λ. High production rates are possible, improved further by the use of multi cavity tools. λ. 100% material yield. Why Choose LANCOR for Die Casting?  LANCOR’s design assistance, prototype and value-added/sub-assembly services ensure customers of its commitment to success from the inception of a program to the final product.From design concept to production and packaging, LANCOR is a professional leader in die casting, a full service of precision aluminum die castings components servicing the medical die casting mold, LED lamp die casting mold, electronics die casting mold, automotive die cast mold, microwave die cast mold, general hardware die casting mold and a variety of other industries. LANCOR handles all aspects of aluminum die casting from mold design and testing, to aluminum / zinc component manufacturing, finishing, and packaging. With many years of experience and technical expertise in aluminum /zinc die casting enable LANCOR to produce tight-tolerance, complex components in a cost-effective and timely manner. Timely delivery is protocol for us, so you can rest assured your shipment will arrive on time. LANCOR’s design assistance, prototype and value-added/sub-assembly services ensure customers of its commitment to success from the inception of a program to the final product.From design concept to production and packaging, LANCOR is a professional leader in die casting, a full service of precision aluminum die castings components servicing the medical die casting mold, LED lamp die casting mold, electronics die casting mold, automotive die cast mold, microwave die cast mold, general hardware die casting mold and a variety of other industries. LANCOR handles all aspects of aluminum die casting from mold design and testing, to aluminum / zinc component manufacturing, finishing, and packaging. With many years of experience and technical expertise in aluminum /zinc die casting enable LANCOR to produce tight-tolerance, complex components in a cost-effective and timely manner. Timely delivery is protocol for us, so you can rest assured your shipment will arrive on time.Die Casting of Aluminum  because it is very cost effective. It is light-weight yet can withstand the highest operating temperatures of all the die cast alloys. It’s non magnetic, has good corrosion resistance and is also an excellent electrical conductor. Aluminum helps fuel efficiency and has many uses in the transport industry due to its unbeatable strength to weight ratio. because it is very cost effective. It is light-weight yet can withstand the highest operating temperatures of all the die cast alloys. It’s non magnetic, has good corrosion resistance and is also an excellent electrical conductor. Aluminum helps fuel efficiency and has many uses in the transport industry due to its unbeatable strength to weight ratio.Aluminum is molded at high pressure, which requires the tooling to have exact tolerances and good sealing surfaces to contain the material being molded which has a consistency like water. There are advantages to die cast aluminum parts, such as a high strength to weight ratio. Another advantage of aluminum is that it can be readily recycled. Recycling uses a fraction of the energy required to manufacture virgin material. Die cast aluminum is used in parts such as outer and inner caps, continuous couples and various types of bracket. Die Casting of zinc  Zinc is a corrosion-resistant material with good mechanical properties. The main difference between zinc and aluminum is the weight: zinc is 2.5 times heavier, but has inferior heat resistant properties and a lower creep strength. The advantages of zinc are that it is easier to mould, melts at a lower temperate and is therefore gentler on the tool. A properly made zinc tool can handle close to 1 million cycles with good quality results and high repetition precision. Zinc is a corrosion-resistant material with good mechanical properties. The main difference between zinc and aluminum is the weight: zinc is 2.5 times heavier, but has inferior heat resistant properties and a lower creep strength. The advantages of zinc are that it is easier to mould, melts at a lower temperate and is therefore gentler on the tool. A properly made zinc tool can handle close to 1 million cycles with good quality results and high repetition precision.With zinc it possible to produce thin products with a high finish on the surfaces, important for the treatment of visible surfaces such as chrome or nickel-plating. The parts are usually ready for use immediately following die casting with no further shaping required except, occasionally, for rolling. The areas of application are the same as for aluminum, but zinc is better suited for applications which require a significantly higher measurement tolerance or finer requirements for the surfaces. Die Casting Application

If this product Not the products you want: Mail , Or click here Post a buy information about product to us. |